Inspection Checklist

Reasons Why Businesses Should Use an Inspection Checklist on Their Equipment and Vehicles

Inspections of equipment and vehicles are a critical component of maintaining a safe and functional work environment. It is essential to inspect and document equipment and vehicles before using them. The inspection will identify and document any potential issues that could cause harm or damage.

In this post, we will provide a comprehensive guide on how to conduct daily or pre-use inspections effectively.

What is an Inspection?

An inspection is a detailed, in-depth visual and operational examination of equipment or machinery before it is used. It is an essential process that ensures that the equipment is safe to use and in good working condition. Inspections can help reduce equipment failure and reduce the risk of injury or accidents in the workplace.

Inspections should ideally be conducted by qualified personnel who have received adequate training and have the necessary knowledge and skills to inspect equipment and identify any defects or faults. It is crucial to follow the manufacturer’s guidelines and procedures when conducting pre-use inspections to ensure that the equipment is safe to use.

Why are Inspections Important?

As a business owner, you want to ensure your employees’ safety, your equipment’s longevity, and your company’s profitability. One way to achieve all of these goals is to implement a daily or pre-use inspection checklist for your equipment and vehicles. In this post, we will explore the reasons why businesses should have an inspection checklist and how it can benefit their operations.

Improved Safety

The safety of your employees is always a top priority. By implementing an inspection checklist, you can identify potential hazards with your equipment and vehicles and address them before they cause harm. A checklist will ensure that the inspection is completed according to a well-thought-out plan ensuring there are no leaks or damage to the equipment and that all safety hardware and systems on the equipment or vehicle are present and in working order. As a business owner or manager, you can greatly reduce accidents and injuries by having your equipment and vehicle operators take a few minutes to check their equipment before each use.

Increased Equipment Longevity

Regular maintenance is essential to the reliability and longevity of your equipment. An inspection checklist will help you identify and address any issues with your equipment before they become larger problems. By dealing with issues early, you can prevent costly repairs and extend the life of your equipment. Additionally, a pre-use checklist can help ensure that your equipment is being used properly, preventing damage and reducing repair costs.

Compliance with Regulations

Many industries have regulations in place that require businesses to inspect their equipment regularly. By implementing a checklist, you can ensure that you meet these regulations and avoid potential fines or legal issues. A pre-use checklist can also help you identify any areas where you may not be complying, allowing you to make the necessary changes to meet regulations.

Reduced Liability

You are all aware of the legal liabilities that surround company-owned equipment and vehicles. Every lawyer is rushing to get a case involving company-owned equipment and vehicles. Having regular, detailed, documented inspections will greatly reduce your legal liabilities and might even reduce your insurance premiums.

Improved Efficiency

By inspecting your equipment before each use, you can identify any issues that may slow down your operations. For example, if a piece of equipment is not functioning correctly, you must discover the issue before the equipment leaves for the job site. That means that you can address the issue before it causes a delay in your operations. Additionally, by ensuring that your equipment is in good working condition, you can prevent breakdowns that could cause significant downtime and lost productivity.

Cost Savings

Preventative maintenance is always more cost-effective than reactive maintenance. You can avoid costly repairs and reduce downtime by catching issues early and addressing them promptly. Additionally, by extending the life of your equipment, you can reduce the need for new equipment purchases, which can be a significant expense for businesses.

By inspecting your equipment before each use, you can reduce accidents and injuries, identify and address issues before they become larger problems, and improve your business’s overall efficiency and profitability.

How can we get a checklist that we can use for any piece of equipment or vehicle?

Inspections are frequently performed on motor vehicles and heavy equipment. Due to the very nature of these vehicles and heavy equipment, these inspections can be incredibly complicated and detailed.

Inspections should be conducted by qualified personnel who have received adequate training and have the necessary knowledge and skills to inspect the equipment and identify any defects or faults. It is crucial to follow the manufacturer’s guidelines and procedures when conducting inspections to ensure that the equipment is safe to use.

Unfortunately, in the real world, our experience with many businesses is that the inspection will more often than not be performed by the equipment operator on that given day.

When the inspection checklist has been completed and turned in, it then serves as the written report that documents the inspection.

Two Approaches to Inspections

There are two distinct methods that you can use in your approach to doing the inspection and then documenting the results of that inspection into a report that the company can use to guide them in maintaining that piece of equipment.

Rely only on the knowledge and abilities of the person doing the inspection.

Using this approach poses several big problems. The different operators of any given vehicle or piece of equipment frequently have wildly different levels of knowledge and ability to document the results of their inspection.

Provide a detailed checklist to the operator of the equipment or vehicle.

Of the two different approaches, it would seem logical to use the second approach.

Example of Using a Checklist for an Excavator Inspection

Here’s an example of how to use a checklist to conduct a pre-use inspection of an excavator:

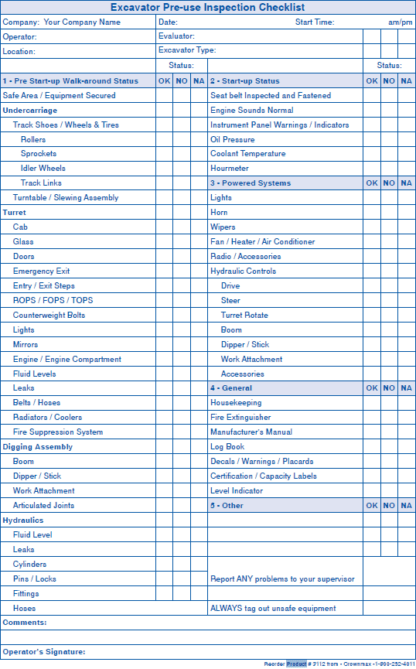

Title: 3112 – Excavator Pre-Use Inspection Checklist

This is an example of how to do a pre-use inspection of an excavator using a Crownmax checklist. The checklist form contains fields to enter specific data about the equipment being inspected. The checklist is designed to be user-friendly and comprehensive.

To conduct a pre-use inspection using a checklist, follow these steps:

Link to example: 3112 – Excavator Pre-Use Inspection Checklist

Document the data on the specific piece of equipment that is to be inspected

At the top of the checklist form, fill in the fields that require data about the specific piece of equipment that will be inspected and used.

Use the checklist to perform and document the inspection

Start at the top of the left column with “Step 1 – Pre Start-up Walk-around Status” and check each line as you work through the checklist. The checklist provides three columns for each line: “OK,” “NO,” and “NA.” This makes it easy to document the results of the inspection consistently.

The checklist can be printed as a booklet and kept in the equipment for easy access. Using the checklist ensures that the pre-use inspections are completed to an accepted standard and that the documented results are in a standard format that provides useful information for equipment maintenance.

Pre-use inspections are an essential component of maintaining a safe and functional work environment. By conducting regular pre-use inspections, you can prevent accidents, reduce downtime, and comply with legal requirements.

If you’re not already using a pre-use inspection checklist, now is the time to start. Crownmax offers a complete selection of checklists, including Vehicle Inspection Reports, Accident Reports, and Multi-Point Vehicle Inspection Reports. We also provide inspection checklists for various equipment types, such as Pulling Equipment, UTVs, Pick-up Trucks, Crew Haulers, Forklifts, Off Road Forklifts, Excavators, Drills, Diggers, Dozers, Bucket Trucks, Cranes, and Derricks.

Implementing an inspection checklist specific to each piece of equipment or vehicle will ensure thorough inspections and consistent documentation. It will help businesses maintain safety standards, prolong the life of equipment, comply with regulations, reduce liability, improve efficiency, and achieve cost savings.

By prioritizing inspections and utilizing checklists, businesses can proactively address potential issues, enhance workplace safety, and optimize operations. So, don’t wait any longer—start using inspection checklists today and reap the benefits of a well-maintained and secure work environment. Crownmax is here to assist you with a comprehensive selection of checklists tailored to different equipment types.